The main structure of the screen printing machine: transmission device: motor,Silk screen Machine electromagnetic clutch, reducer, speed regulating mechanism. Printing plate device: The screen printing plate must be fixed on the printing plate device in the screen printing machine. During the printing process,Silk screen Machine the lifting and lowering or horizontal lifting can be realized. Mainly include: printing plate holder,Silk screen Machine printing plate lifting mechanism,Silk screen Machine plate adjustment mechanism, net lifting compensation mechanism.

Printing device: Scraper and ink return are the main actions to achieve silk screen printing. The ink squeegee system and the ink return system are usually installed on the squeegee carriage. During the reciprocating motion,Silk screen Machine the squeegee and the ink return plate are alternately raised and lowered, respectively. Realize ink scraping and ink return action. The realization of printing reciprocating stroke generally adopts the following mechanisms: crank connecting rod mechanism, crank slider mechanism, chain sprocket mechanism,Silk screen Machine cylindrical plug magnetic cylinder. The guide mechanism generally adopts the following forms: roller groove rail, double guide shaft,Silk screen Machine guide shaft plus slider.

The scraping and ink return plate transposition mechanism often adopts the following forms: step groove lifting striker plus lever transposition mechanism, cam lifting mechanism plus lever transposition mechanism,Silk screen Machine two-cylinder reverse action or single cylinder plus lever mechanism, cam-swing rod mechanism Pulling the steel wire and lever mechanism,Silk screen Machine the hanging point of the chain changes to make the two plates swing at an angle. When a scraper is used to replace two scrapers,Silk screen Machine an ink jumping action is required, and the ink jumping action is completed by a specific mechanism.

The supporting device is the printing platform: it is used to fix the printing material. It should have a printing positioning device. The height and level adjustment device of the platform. Plate registration mechanism: The platform position movement during plate registration is generally realized by mechanical screwing,Silk screen Machine and should have a reliable locking device and displacement guide (dovetail groove or feather key, etc.). Drying device: infrared electric heating tube hot air drying or ultraviolet curing drying device. Electrical control device: working cycle control, scraper position control,Silk screen Machine air pressure control.

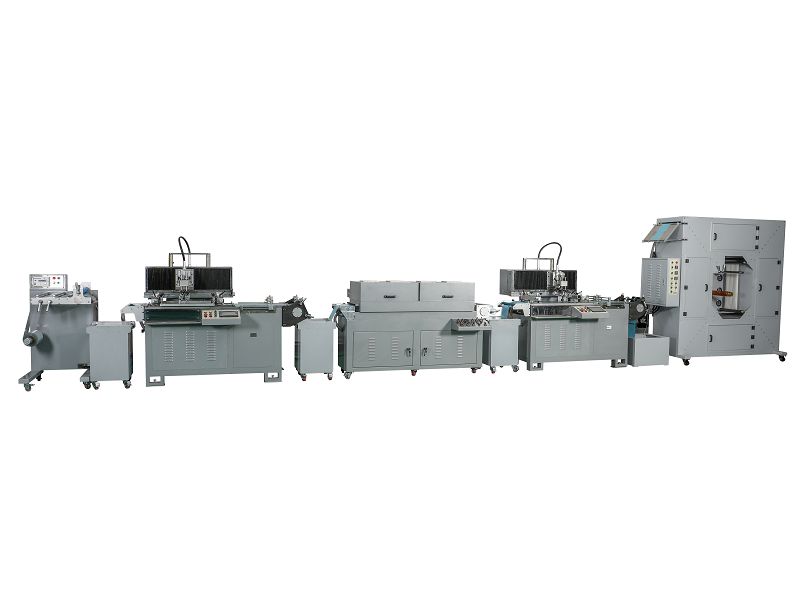

The screen printing machine is a machine that uses a screen printing plate to print,Silk screen Machine and belongs to a type of printing machine. The screen printer is a machine that prints text and images,Silk screen Machine and is a general term for machines or equipment used to produce printed products. The screen printing machine belongs to the more representative printing equipment in the stencil printing machine. In addition to real silk, the material for making the screen can also be nylon wire, copper wire,Silk screen Machine steel wire or stainless steel wire. It can be divided into flat screen printing machine, curved screen printing machine,Silk screen Machine rotary screen printing machine and so on.

Post time: Sep-17-2022